Format: PDF

Language: EN

Size: 4.26 MB

Pages: 142

Speed Download Link

$40 Original price was: $40.$30Current price is: $30.

Part One: Article

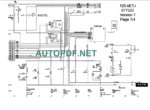

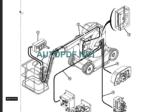

Title: Mastering Equipment Maintenance: Your Guide to the 120 AETJ Repair

Introduction:

The 120 AETJ is a reliable and powerful equipment utilized in various industries for its exceptional performance. To ensure its seamless operation and address any maintenance or repair needs, a comprehensive repair manual is essential. The 120 AETJ Repair Manual is a valuable resource that provides detailed instructions and insights into key components of this equipment. In this article, we will explore four critical areas covered in the repair manual: Engine, Transmission, Axle Assembly, and Hydraulic System. By following the guidelines outlined in these sections, operators and technicians can effectively maintain and troubleshoot the 120 AETJ, ensuring optimal performance and longevity.

Engine:

The engine is the heart of the 120 AETJ equipment, providing the power necessary for its operation. The repair manual provides detailed instructions on engine maintenance, including regular oil changes, filter replacements, and thorough inspections. Adhering to these maintenance procedures ensures the engine’s reliability, enhances fuel efficiency, and extends its lifespan, resulting in improved overall equipment performance.

Transmission:

The transmission system of the 120 AETJ is responsible for transferring power from the engine to the wheels. The repair manual covers various aspects of transmission maintenance, including fluid checks, filter replacements, and adjustment procedures. By following these guidelines, operators can ensure smooth gear shifting, optimize transmission performance, and prevent premature wear and tear.

Axle Assembly:

The axle assembly of the 120 AETJ is vital for the equipment’s stability and maneuverability. The repair manual provides comprehensive information on axle assembly maintenance, including lubrication, inspection of bearings, and alignment procedures. Proper maintenance of the axle assembly ensures optimal performance, prevents excessive wear, and enhances overall equipment safety.

Hydraulic System:

The hydraulic system plays a critical role in the operation of the 120 AETJ, enabling precise lifting and positioning capabilities. The repair manual provides guidelines for hydraulic system maintenance, including fluid checks, filter replacements, and inspection of hydraulic components. By following these recommendations, operators can ensure the efficient functioning of the hydraulic system, minimizing downtime and maximizing productivity.

Conclusion:

The 120 AETJ Repair Manual is an indispensable resource for operators and technicians, offering detailed instructions for maintaining and troubleshooting the engine, transmission, axle assembly, and hydraulic system of the equipment. By following the guidelines provided in these sections, operators can ensure the reliable performance and extended lifespan of the 120 AETJ, ultimately enhancing productivity and safety across various applications.