Format: PDF

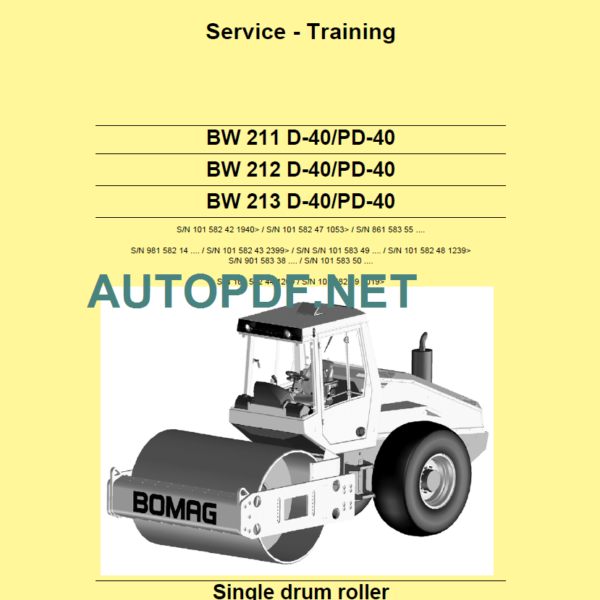

Serial Number: S/N 101 582 42 1940> / S/N 101 582 47 1053> / S/N 861 583 55 S/N 981 582 14 / S/N 101 582 43 2399> / S/N S/N 101 583 49 / S/N 101 582 48 1239> S/N 901 583 38 / S/N 101 583 50 S/N 101 582 44 1209 / S/N 101 582 49 1019>

Catalogue Number: 008 919 68

Language: EN

Size: 19.42MB

Pages: 468

Speed Download Link

$40 Original price was: $40.$30Current price is: $30.

The BW 212 PD D-40 is a powerful and reliable soil compactor that helps in construction sites around the world. However, like any machine that is subject to heavy usage, it requires proper care and maintenance to ensure optimal performance. Investing in BW 212 PD D-40 service training is essential to help operators and technicians prevent costly repairs and equipment downtime.

Here are four integral parts of the BW 212 PD D-40 operators and technicians should understand in detail:

Technical Data: The equipment’s technical data provides critical information about weight, dimensions, and performance specifications that operators must know to identify operational inefficiencies and ensure they operate at maximum capacity.

Engine: The engine is the force behind the machine’s various functions, making it one of the most important components. Knowing its specifications and functions is crucial to diagnosing issues quickly, reducing costly downtime, and optimizing the equipment’s lifespan.

Circuit Diagrams: A breakdown in the electrical system can lead to costly repairs. Therefore, understanding circuit diagrams and electrical systems can help operators troubleshoot issues early, allowing them to get back to work as soon as possible.

Hydraulic: A thorough understanding of the hydraulic system can reduce machine repair costs and minimize downtime. Hydraulic maintenance is vital to ensure optimal performance and proper care and performance.

Comprehensive knowledge about these four components together with other critical systems like the hydraulic and electric system will ensure higher efficiency in function. This knowledge will also allow the operators and technicians to maintain the machine better, optimize equipment operations and avoid costly repairs and downtime.