Format: PDF

Serial Number: SN 101 921 21 1022

Catalogue Number: 008 200 61

Language: EN

Size: 6.26 MB

Pages: 288

Speed Download Link

$40 Original price was: $40.$30Current price is: $30.

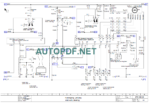

The BW 170-174 AD is a series of powerful and versatile compactors used in various construction and road-building projects. To ensure these machines operate at peak performance and provide reliable results, it is essential for operators and technicians to undergo BW 170-174 AD Service Training. This comprehensive training covers various aspects of the compactor, including technical data, engine functionality, circuit diagrams, drum operation, hydraulic systems, and the electric system.

In conclusion, the BW 170-174 AD Service Training provides invaluable knowledge and skills to operators and technicians, enhancing the performance and reliability of these compactors. By mastering technical data, engine functionality, circuit diagrams, drum operation, and hydraulic and electrical systems, trainees can ensure the BW 170-174 AD compactors deliver exceptional results in construction and road-building projects.