Format: PDF

Language: EN

File Size: 18.78 MB

Pages: 467

Printable Content

$40 Original price was: $40.$35Current price is: $35.

2 SAFETY

2.1 SAFETY INFORMATION

2.2 OVERVIEW

2.3 SOUND PRESSURE LEVEL IN THE OPERATOR’S CAB.

2.4 GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

2.5 PRECAUTION FOR MAINTENANCE

2.6 ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS

2.7 SPECIAL SAFETY EQUIPMENT

2.8 ADDITIONAL SAFETY PRECAUTIONS

3 GENERAL

3.1 GENERAL

3.2 ASSEMBLY SITE REQUIREMENTS

3.3 LIFTING OF THE MAIN COMPONENTS

3.4 GENERAL INSTALLATION PROCEDURES FOR HYDRAULIC HOSE LINES

4 ASSEMBLY SEQUENCE

4.1 ASSEMBLY SEQUENCE OF FACE SHOVEL MACHINES

4.2 ASSEMBLY SEQUENCE OF BACKHOE MACHINES

4.3 ASSEMBLY OF UNDERCARRIAGE

4.4 MOUNTING SUPERSTRUCTURE PLATFORM ONTO UNDERCARRIAGE

4.5 ASSEMBLY OF MACHINERY HOUSE ROOF

4.6 MOUNTING MACHINERY HOUSE ONTO THE SUPERSTRUCTURE PLATFORM

4.7 MOUNTING OF HYDRAULIC ACCESS LADDER

4.8 CONNECTING ENGINE OIL RESERVE SYSTEM

4.9 PRE-ASSEMBLY OF FACE SHOVEL BOOM

4.10 PRE-ASSEMBLY OF BACKHOE BOOM

4.11 MOUNTING OF COUNTERWEIGHT

4.12 MOUNTING OF THE FUEL TANK

4.13 ATTACHING THE CAB BASE

4.14 ATTACHING THE CAB WITH SUPPORT FRAME TO THE CAB BASE

4.15 CONNECTING HIGH PRESSURE HOSES FROM MAIN PUMPS TO CHECK VALVES

4.16 ATTACHING INTERMEDIATE PIPE TO THE SUCTION OIL RESERVOIR

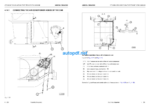

4.17 ATTACHING THE HYDRAULIC OIL RESERVOIR

4.18 ATTACHING THE HYDRAULIC OIL COOLER

4.19 CONNECTING HYDRAULIC LINES TO THE ROTARY JOINT

4.20 ATTACHING THE HANDRAILS, CATWALKS AND STEPS

4.21 ATTACHING THE CENTRAL LUBRICATION UNIT

4.22 CENTRAL REFILLING SYSTEM

4.23 MOUNTING CAN-NODE BOXES ON MACHINERY HOUSE ROOF

4.24 PRE-CHECKS PRIOR TO INITIAL START UP

4.25 FILLING AND BLEEDING THE HYDRAULIC SYSTEM

4.26 BLEEDING GEAR PUMPS FOR PTO GEAR LUBRICATION

4.27 ASSEMBLY FACE SHOVEL ATTACHMENT

4.28 BLEEDING HYDRAULIC CIRCUITS

4.29 ATTACHING FACE SHOVEL TO THE STICK

4.30 ASSEMBLY BACKHOE ATTACHMENT

4.31 BLEEDING HYDRAULIC CIRCUITS

4.32 ATTACHING BACKHOE BUCKET TO THE STICK

4.33 BLEEDING HYDRAULIC CIRCUITS OF THE TRAVEL MOTORS

5 FINAL CHECKS AND ADJUSTMENTS

5.0.1 COMMISSIONING CHECK LIST

5.0.2 ADJUSTMENT OF AUTOMATIC LUBRICATION SYSTEMS

5.0.3 MAIN PUMP ADJUSTMENT IN RELATION TO ALTITUDE AT THE MINE SITE

5.0.4 PRESSURE COMPENSATION OF SEALED COMPONENTS

5.1 PLACING THE FIRE DETECTION AND SUPPRESSION SYSTEM IN SERVICE

5.2 COMMISSIONING OF THE AIR CONDITIONING

5.3 PERFORM THE PM-CLINIC ACCORDING TO THE PM-CLINIC PROCEDURE MANUAL

5.4 HANDLING OF DOCUMENTATION AFTER ASSEMBLY AND COMMISSIONING

6 ORBCOMM INITIALIZATION

6.1 ORBCOMM TERMINAL ACTIVATION

6.2 WEBCARE BASIC INFORMATION FOR MACHINE REGISTRATION

7 DISASSEMBLY OF THE MACHINE

7.0.1 DISASSEMBLY SEQUENCE OF FACE SHOVEL MACHINES

7.0.2 SAFETY PRECAUTIONS FOR DISASSEMBLING THE MACHINE

7.0.3 DISASSEMBLY SEQUENCE OF BACKHOE MACHINES

7.0.4 SAFETY PRECAUTIONS FOR DISASSEMBLING THE MACHINE

7.0.5 DISPOSAL OF WASTE MATERIAL

7.0.6 LIFTING AND TRANSPORTATION OF MAIN COMPONENTS

8 LIFTING AND TRANSPORTATION OF MAIN COMPONENTS

8.1 LIFTING OF THE MAIN COMPONENTS

8.2 TRANSPORTATION OF THE MAIN COMPONENTS