Format: PDF (Printable Document)

Language: EN

File Size: 11.22 MB (Speed Download PDF)

Pages: 75

Download Link, Editable Content

$40 Original price was: $40.$35Current price is: $35.

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE

WORKFLOW OF MAJOR ASSEMBLY WORK AT THE JOB SITE

ASSEMBLY KIT LAYOUT DRAWING.

PACKING STYLE FOR PRIOR TO TRANSPORTATION

LIST OF SEPARATELY SHIPPED PARTS

LIST OF TOOLS FOR FIELD ASSEMBLING.

TIGHTENING TORQUE.

COATING MATERIALS LIST

A ASSEMBLY PROCEDURE

A-I. Setting of machine.

A-2 Installing grip for getting onloff

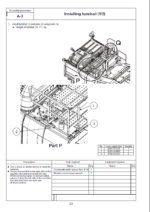

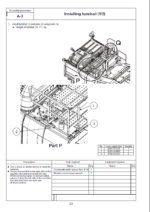

A-3 Installing handrail (1/2, 2/2)

A-4. Installing exhaust pipe

A-5. Installation of feeder hopper (1/5 – 5/5)…

A-6- Installation of belt conveyor (1/9 – 9/9).-

A-T Installation of magnetic separator assembly (1/2, 2/2)

A-8. Installing swing jaw plate (1/3 – 3/3) .

A-9. Installing mirror (1/3 – 3/3)….

M- INSPECTION AND SERVICING PROCEDURES AFTER ASSEMBLY

M-1. Inspection of oil levels and coolant levels (1/2, 2/2)

M-2. Bleeding air from hydraulic circuit (1/3 – 3/3)

M-3. Exchanging parts of return filter (From standard parts to flushing-dedicated parts).

M-4

Flushing of hydraulic circuit

M-5. Exchanging parts of return filter (From flushing-dedicated parts to standard pans)

(1/2, 2/2)

M-6. Checking errors

FIELD ASSEMBLY INSPECTION REPORT

GEN00176-01

SERIAL NUMBERS 5001 and up