Format: PDF

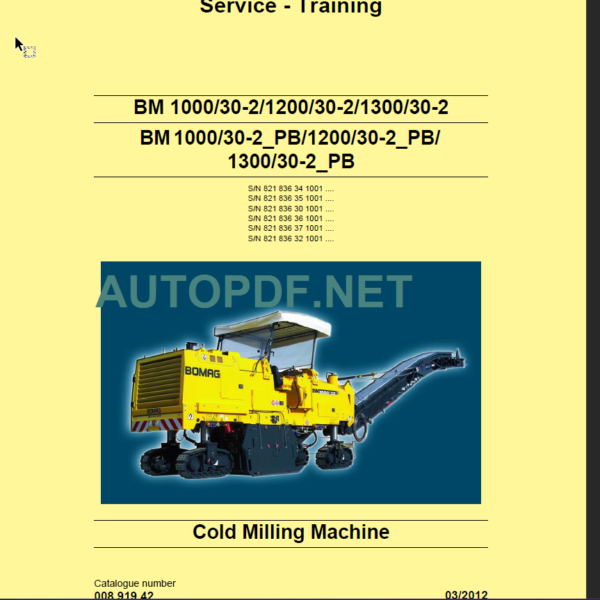

Serial Number: S/N 821 836 34 1001 S/N 821 836 35 1001 S/N 821 836 30 1001 S/N 821 836 36 1001 S/N 821 836 37 1001 S/N 821 836 32 1001

Catalogue Number: 008 919 42

Language: EN

Size: 15.55 MB

Pages: 330

Speed Download Link

$40 Original price was: $40.$30Current price is: $30.

Regular servicing and maintenance are crucial for ensuring the optimal performance and long lifespan of your BM 1000-1200-1300 30-2 (PB) road milling machine. The BM 1000-1200-1300 30-2 (PB) Service Training manual provides comprehensive instructions for maintaining and repairing the machine, covering technical data, engine components, circuit diagrams, hydraulic and electric systems, and drum components. In this article, we will explore four sections of the manual that are essential for keeping your machine functioning smoothly.

The technical data section of the manual provides critical information about the machine’s capabilities and specifications, including engine power, weight, and dimensions. This information is indispensable for diagnosing any issues that may affect the performance of your machine.

The engine section of the manual covers the power unit, including the cooling, lubrication, and air filtration systems. The engine is a crucial component of the machine, and proper maintenance and servicing of its components can help prevent engine breakdown and ensure long-term performance.

The circuit diagrams section of the manual details the machine’s electrical components, including sensors, relays, switches, and wiring. This section provides valuable instructions on troubleshooting electrical issues that may arise and can help prevent unnecessary downtime due to electrical failures.

The hydraulic section of the manual provides detailed instructions on the maintenance and servicing of the machine’s hydraulic components, including pumps, hoses, and valves. It includes information on proper oil levels, inspections for leaks, and checking hoses for damage, ensuring that your machine’s hydraulic system is functioning optimally.

In conclusion, the BM 1000-1200-1300 30-2 (PB) Service Training manual is an essential resource for maintaining and repairing your machine. The manual provides detailed instructions on maintaining and servicing technical data, engine components, circuit diagrams, hydraulic and electric systems, and drum components, ensuring that your machine operates optimally for many years.