Format: PDF

Catalogue Number: 008 191 32

Language: EN

Size: 12.95 MB

Pages: 318

Speed Download Link

$40 Original price was: $40.$30Current price is: $30.

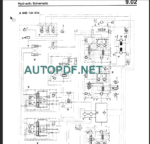

The BW 161 AD is a robust and reliable compactor used in various construction projects. To ensure its longevity and peak performance, having access to BW 161 AD Repair Instruction is essential. This comprehensive guide covers technical data, engine maintenance, drum functionality, hydraulic system, and the electric components. By understanding and following these repair instructions, operators and maintenance personnel can effectively troubleshoot issues and keep the BW 161 AD in top-notch condition.

In conclusion, the BW 161 AD is an indispensable resource for anyone operating or maintaining this compactor. By mastering technical data, engine maintenance, drum functionality, hydraulic system, and electric components, operators can maximize the BW 161 AD’s efficiency and ensure its long-term reliability.