Format: PDF

Language: EN

File Size: 21.89 MB

Pages: 701

Printable Content

$40 Original price was: $40.$35Current price is: $35.

GENERAL

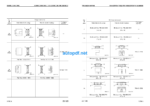

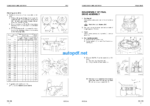

SPECIFICATION DRAWINGS

FUEL, COOLANT AND LUBRICANTS

PTO

PTO LUBRICATION SYSTEM

POWER TRAIN SWING MACHINERY SWING CIRCLE

FINAL DRIVE

TRACK FRAME AND RECOIL SPRING

IDLER CARRIER ROLLER

TRACK ROLLER

TRACK SHOE ( 1/ 2)

( 2/ 2)

MOTOR GREASE PUMP

HYDRAULIC TANK

HYDRAULIC PUMP

LINE OIL FILTER

PILOT OIL FILTER

DRAIN OIL FILTER

L. H. 5- SPOOL CONTROL VALVE

R. H. 4- SPOOL CONTROL VALVE

STRAIGHT- TRAVEL VALVE

SWING MOTOR

CENTER SWIVEL JOINT

TRAVEL MOTOR

PPC CONTROL RELIEF VALVE

SAFETY LOCK VALVE

PPC ACCUMULATOR

VALVE CONTROL

WORK EQUIPMENT, SWING PPC VALVE

TRAVEL PPC VALVE

SOLENOID VALVE

HYDRAULIC CYLINDER

WORK EQUIPMENT

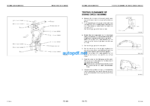

DIMENSIONS OF WORK EQUIPMENT

AIR CONDITIONER

ENGINE CONTROL

MACHINE CONTROL SYSTEM

MONITOR SYSTEM

SENSORS

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

STANDARD VALUE TABLE FOR CHASSIS

STANDARD VALUE TABLE FOR ELECTRICAL PARTS

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

MEASURING AIR SUPPLY PRESSURE ( BOOST PRESSURE)

MEASURING EXHAUST TEMPERATURE

MEASURING EXHAUST COLOR

ADJUSTING VALVE CLEARANCE

MEASURING BLOW- BY PRESSURE

MEASURING COMPRESSION PRESSURE

MEASURING ENGINE OIL PRESSURE

HANDLING EQUIPMENT IN FUEL CIRCUIT

RELEASING REMAINING PRESSURE IN FUEL SYSTEM

MEASURING FUEL PRESSURE

REDUCED CYLINDER MODE OPERATION FOR ENGINE

BLEEDING AIR FROM FUEL CIRCUIT

CHECKING FOR LEAKAGE IN FUEL CIRCUIT

TESTING AND ADJUSTING ALTERNATOR BELT TENSION

TESTING AND ADJUSTING FAN BELT TENSION

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR DRIVE BELT TENSION

HANDLING ENGINE CONTROL- LER HIGH VOLTAGE CIRCUIT

ADJUSTING ENGINE SPEED SENSOR

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE

TESTING AND ADJUSTING PISTON PUMP CONTROL PRESSURE

MEASURING SERVO PISTON STROKE

MEASURING PPC VALVE OUT- PUT PRESSURE

TESTING SOLENOID VALVE OUTPUT PRESSURE

ADJUSTING WORK EQUIP- MENT, SWING PPC VALVE

TESTING TRAVEL DEVIATION

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

MEASURING OIL LEAKAGE

TESTING CLEARANCE OF SWING CIRCLE BEARING

TESTING AND ADJUSTING TRACK SHOE TENSION

BLEEDING AIR

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

PROCEDURE FOR CHECKING DIODE

POINTS TO REMEMBER WHEN TROUBLESHOOTING

SEQUENCE OF EVENTS IN TROUBLESHOOTING POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE CHECKS BEFORE TROUBLESHOOTING

CONNECTOR TYPES AND MOUNTING LOCATIONS

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

METHOD OF USING JUDGEMENT TABLE

METHOD OF USING TROUBLESHOOTING CHARTS

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

N- 1 [ E117, E118 occur at same time ] Monitor panel communication abnormality

N- 2 [ E117, E218 occur at same time ] Engine controller communication abnormality

N- 3 [ E118, E955 occur at same time ] Pump controller communication abnormality

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED

E- 1 [ E91b ] ( Abnormality in engine speed Ne sensor system) is displayed

E- 2 [ E91C ] ( Abnormality in engine G rotation sensor system) is displayed

E- 3 [ E920 ] ( Abnormality in model selection system) is displayed

E- 4 [ E922 ] ( Engine overrun) is displayed

E- 5 [ E924 ] ( Drop in engine oil pressure) is displayed

E- 6 [ E931 ] ( Abnormality in fuel control dial sensor system) is displayed

E- 7 [ E934 ] ( Abnormality in engine water high- temperature sensor system) is displayed

E- 8 [ E936 ] ( Abnormality in engine oil pressure switch system) is displayed

E- 9 [ E93C ] ( Abnormality in boost pressure sensor system) is displayed

E- 10 [ E93d ] ( Abnormality in fuel temperature sensor system) is displayed

E- 11 [ E954 ] ( Short circuit in starting switch C system) is displayed

12 [ E955 ] ( Abnormality in network system) is displayed

E- 13 [ E956 ] ( Power source system abnormality 1) is displayed

E- 14 [ E957 ] ( Power source system abnormality 2) is displayed

15 [ E95A ] ( Abnormality in fuel injection amount adjustment switch signal) is displayed

E- 16 [ E96A ] ( Abnormality in engine water low- temperature sensor system) is displayed

E- 17 [ E970 ] ( Excess current in fuel supply pump PCV1 system) is displayed

E- 18 [ E971 ] ( Excess current in fuel supply pump PCV2 system) is displayed

E- 19 [ E974 ] ( Disconnection in fuel supply pump PCV1 system) is displayed

E- 20 [ E975 ] ( Disconnection in fuel supply pump PCV2 system) is displayed

E- 21 [ E977 ] ( Abnormality in common rail fuel pressure sensor system) is displayed

E- 22 [ E979 ] ( Common rail fuel high pressure abnormality 1) is displayed [ E97A ] ( Common rail fuel high pressure abnormality 2) is displayed

E- 23 [ E97b ] ( Fuel supply pump non- force feed 1) is displayed [ E97C ] ( Fuel supply pump non- force feed 2) is displayed

E- 24 [ E97d ] ( Abnormality in common rail fuel pressure) is displayed

E- 25 [ E980 ] ( Defective engine controller) is displayed

E- 26 [ E981 ] ( Disconnection in No. 1 fuel injector system) is displayed

E- 27 [ E982 ] ( Disconnection in No. 2 fuel injector system) is displayed

E- 28 [ E983 ] ( Disconnection in No. 3 fuel injector system) is displayed

E- 29 [ E984 ] ( Disconnection in No. 4 fuel injector system) is displayed

E- 30 [ E985 ] ( Disconnection in No. 5 fuel injector system) is displayed

E- 31 [ E986 ] ( Disconnection in No. 6 fuel injector system) is displayed

E- 32 [ E98A ] ( Short circuit in No. 1, No. 2, No. 3 fuel injector system) is displayed

E- 33 [ E98b ] ( Short circuit in No. 3, No. 4, No. 5 fuel injector system) is displayed

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM ( C MODE)

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

POINTS TO REMEMBER WHEN TROUBLESHOOTING CONTROLLER SYSTEM

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS

C- 1 Abnormality in controller power source system ( controller LED is OFF)

C- 1 Related electrical circuit diagram

TROUBLESHOOTING C- 2

C- 2 [ E232 ] Short circuit in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 2 C- 2 Related electrical circuit diagram TROUBLESHOOTING C- 3

C- 3 [ E233 ] Disconnection in pump TVC solenoid system is displayed

TROUBLESHOOTING C- 3 C- 3 Related electrical circuit diagram TROUBLESHOOTING C- 4

C- 4 [ E203 ] Short circuit in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 4 C- 4 Related electrical circuit diagram TROUBLESHOOTING C- 5

C- 5 [ E213 ] Disconnection in swing holding brake solenoid system is displayed

TROUBLESHOOTING C- 5 C- 5 Related electrical circuit diagram TROUBLESHOOTING C- 6

C- 6 [ E201 ] Short circuit in CO cancel solenoid system is displayed

C- 6 Related electrical circuit diagram

TROUBLESHOOTING C- 7

C- 7 [ E211 ] Disconnection in CO cancel solenoid system is displayed

C- 7 Related electrical circuit diagram

TROUBLESHOOTING C- 8

C- 8 [ E202 ] Short circuit in straight- travel solenoid system is displayed

C- 8 Related electrical circuit diagram

TROUBLESHOOTING C- 9

C- 9 [ E212 ] Disconnection in straight- travel solenoid system is displayed

C- 9 Related electrical circuit diagram

TROUBLESHOOTING C- 10

C- 10 [ E204 ] Short circuit in 2- stage relief solenoid system is displayed

C- 10 Related electrical circuit diagram

TROUBLESHOOTING C- 11

C- 11 [ E214 ] Disconnection in 2- stage relief solenoid system is displayed

C- 11 Related electrical circuit diagram

TROUBLESHOOTING C- 12

C- 12 [ E205 ] Short circuit in swing priority selector solenoid system is displayed

C- 12 Related electrical circuit diagram

TROUBLESHOOTING C- 13

C- 13 [ E211 ] Disconnection in swing priority selector solenoid system is displayed

C- 13 Related electrical circuit diagram

TROUBLESHOOTING C- 14

C- 14 [ E206 ] Short circuit in travel speed solenoid system is displayed

C- 14 Related electrical circuit diagram

TROUBLESHOOTING C- 15

C- 15 [ E216 ] Disconnection in travel speed solenoid system is displayed

C- 15 Related electric circuit diagram

TROUBLESHOOTING C- 16

C- 16 [ E217 ] Model selection input error is displayed

TROUBLESHOOTING C- 16 C- 16 Related electrical circuit diagram TROUBLESHOOTING C- 17

C- 17 [ E227 ] Abnormality in engine speed sensor system is displayed

C- 17 Related electrical circuit diagram

TROUBLESHOOTING C- 18

C- 18 Abnormality in machine push- up solenoid system ( no service code displayed)

a) Even when machine push- up switch is set to low pressure, solenoid is not switched ON

C- 19 Related electrical circuit diagram

TROUBLESHOOTING C- 18 b) Even when machine push- up switch is set to high pressure, solenoid is not switched OFF

C- 18 Related electrical circuit diagram

TROUBLESHOOTING C- 19

C- 19 Abnormality in shockless boom solenoid system ( no service code displayed)

a) Shockless mode cannot be canceled ( solenoid is not switched ON)

TROUBLESHOOTING C- 19 C- 19 Related electrical circuit diagram

TROUBLESHOOTING C- 19

b) Shockless mode is not actuated

C- 19 Related electric circuit diagram TROUBLESHOOTING C- 20 C- 20 Related electrical circuit diagram

C- 20 [ E207 ] Short circuit in flash light relay drive system is displayed

TROUBLESHOOTING C- 21

C- 21 Flash light relay does not work

C- 21 Related electrical circuit diagram

TROUBLESHOOTING C- 22

C- 22 [ E231 ] Abnormality ( short circuit) in power source holding relay output system for step light is displayed

C- 22 Related electrical circuit diagram

TROUBLESHOOTING C- 23

C- 23 Step light switch does not work

C- 23 Related electrical circuit diagram

TROUBLESHOOTING C- 24

C- 24 [ E302 ] Short circuit in step light relay drive system is displayed

C- 24 Related electrical circuit diagram

TROUBLESHOOTING C- 25

C- 25 [ 303 ] Disconnection in step light relay drive system is displayed

C- 25 Related electrical circuit diagram

TROUBLESHOOTING C- 26

C- 26 Step light does not light up

C- 26 Related electrical circuit diagram

TROUBLESHOOTING C- 27

C- 27 [ E228 ] Abnormality in auto- deceleration output system is displayed

C- 27 Related electrical circuit diagram

TROUBLESHOOTING OF ENGINE THROTTLE & PUMP CONTROLLER ( INPUT SIGNAL SYSTEM) ( F MODE)

F- 1 [ Bit pattern 20- ( 1) ] Swing oil pressure switch does not light up

TROUBLESHOOTING F- 2 F- 2 Related electrical circuit diagram

F- 2 [ Bit pattern 20- ( 2) ] R. H. travel oil pressure switch does not light up

F- 3 Related electrical circuit diagram TROUBLESHOOTING F- 3

F- 3 [ Bit pattern 20- ( 3) ] Boom LOWER oil pressure switch does not light up

TROUBLESHOOTING F- 4 F- 4 Related electrical circuit diagram

F- 4 [ Bit pattern 20- ( 4) ] Boom RAISE oil pressure switch does not light up

F- 5 Related electrical circuit diagram TROUBLESHOOTING F- 5

F- 5 [ Bit pattern 20- ( 5) ] Arm IN oil pressure switch does not light up

TROUBLESHOOTING F- 6 F- 6 Related electrical circuit diagram

F- 6 [ Bit pattern 20- ( 6) ] Arm OUT oil pressure switch does not light up

F- 7 Related electrical circuit diagram TROUBLESHOOTING F- 7

F- 7 [ Bit pattern 21- ( 1) ] Bucket CURL oil pressure switch does not light up

TROUBLESHOOTING F- 8 F- 8 Related electrical circuit diagram

F- 8 [ Bit pattern 21- ( 2) ] Bucket DUMP oil pressure switch does not light up

F- 9 Related electrical circuit diagram TROUBLESHOOTING F- 9

F- 9 [ Bit pattern 20- ( 5) ] L. H. travel oil pressure switch does not light up

TROUBLESHOOTING F- 10 F- 10 Related electrical circuit diagram

F- 10 [ Bit pattern 21- ( 4) ] Service oil pressure switch does not light up

F- 11 Related electrical circuit diagram TROUBLESHOOTING F- 11

F- 11 [ Bit pattern 21- ( 3) ] Swing lock switch does not light up

TROUBLESHOOTING F- 12 F- 12 Related electrical circuit diagram

F- 12 [ Bit pattern 24- ( 1) ] When step light switch is ON, it does not go out

F- 13 Related electrical circuit diagram TROUBLESHOOTING F- 13

F- 13 [ Bit pattern 24- ( 2) ] When horn switch is ON, it does not go out

TABLE OF FAILURE MODES AND CAUSES

TROUBLESHOOTING TABLE OF FAILURE MODES AND CAUSES

BEFORE CARRYING OUT TROUBLESHOOTING OF HYDRAULIC SYSTEM ( H MODE)

1. Actuation and combination of main pumps

2. Judgement procedure

BEFORE CARRYING OUT TROUBLESHOOTING TROUBLESHOOTING OF HYDRAULIC SYSTEM ( H MODE)

BEFORE CARRYING OUT TROUBLESHOOTING TROUBLESHOOTING OF HYDRAULIC SYSTEM ( H MODE) TROUBLESHOOTING BEFORE CARRYING OUT TROUBLESHOOTING OF HYDRAULIC SYSTEM ( H MODE) Hydraulic circuit diagram after interchanging hoses Method of interchanging hoses TROUBLESHOOTING

TROUBLESHOOTING H- 2

TROUBLESHOOTING H- 2

TROUBLESHOOTING H- 3

H- 3 Related circuit diagram

TROUBLESHOOTING H- 4, H- 5

TROUBLESHOOTING H- 6

a) If work equipment speed ( boom, arm, bucket) is slow or lacks power in normal mode

TROUBLESHOOTING H- 6 b) If boom RAISE speed is slow or lacks power in heavy lift mode

c) If boom LOWER speed is slow or lacks power when machine push- up is ON TROUBLESHOOTING H- 7, H- 8

TROUBLESHOOTING H- 9, H- 10, H- 11

TROUBLESHOOTING H- 12

TROUBLESHOOTING H- 13

a) Direction of deviation is same in FORWARD and REVERSE

TROUBLESHOOTING H- 13 b) Direction of deviation is different in FORWARD and REVERSE

TROUBLESHOOTING H- 14

TROUBLESHOOTING H- 14, H- 15

TROUBLESHOOTING H- 16, H- 17

TROUBLESHOOTING H- 18

TROUBLESHOOTING H- 18

TROUBLESHOOTING H- 19

TROUBLESHOOTING H- 19, H- 20

TROUBLESHOOTING H- 21

TROUBLESHOOTING H- 22

TROUBLESHOOTING H- 23

TROUBLESHOOTING H- 24

TROUBLESHOOTING H- 25

a) When swing holding brake is released

ACTION TAKEN BY MONITOR PANEL WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE

M- 1 [ E101 ] ( Abnormality in error data) or [ E102 ] ( Abnormality in clock data) is displayed

M- 2 [ E103 ] ( Short circuit in buzzer output system) is displayed

M- 3 [ E104 ] ( Air cleaner clogging detection) is displayed

M- 4 [ E108 ] ( Engine water temperature 105

C) is displayed

M- 5 When starting switch is turned ON, none of lamps on monitor panel light up for 3 seconds

M- 6 When starting switch is turned ON, monitor panel lamps all stay lighted up and do not go out

M- 7 When starting switch is turned ON, items lighted up on monitor panel are different from actual machine

M- 8 When starting switch is turned ON ( engine stopped) , basic check items flash

M- 9 Preheating is not being used but preheating display motor lamp lights up

M- 10 When engine is started, basic check items flash

M- 11 When starting switch is turned ON ( engine stopped) , CAUTION items and EMERGENCY STOP items flash

M- 12 When engine is started, CAUTION items and EMERGENCY STOP items flash

M- 13 Operation of alarm buzzer is not normal

M- 14 Night lighting on monitor panel does not light up

M- 15 Engine water temperature display is not normal

M- 16 Fuel level gauge display is not normal

M- 17 Swing lock switch is turned ON but swing lock monitor lamp does not light up

M- 18 When swing brake release switch is set to RELEASE ( EMERGENCY) , swing lock monitor lamp does not flash

M- 19 Service meter does not give normal display

M- 20 Defective fuel level sensor system

M- 21 Defective engine oil level sensor system

M- 22 Defective coolant level sensor system

M- 23 Defective hydraulic oil level sensor system

M- 24 Wiper is not actuated when wiper switch is operated or wiper is actuated when wiper switch is not operated

M- 25 Window washer is not actuated when wiper switch is operated or window washer is actuated when switch is not operated

M- 26 Electric grease gun does not work ( machines equipped with electric grease gun)

METHOD OF USING MANUAL

1. When removing or installing unit assemblies

2.

3. Listing of special tools

A1

DISASSEMBLY AND ASSEMBLY METHOD OF USING MANUAL

6. Tightening torque of split flange bolts

5. Tightening torque of hose nuts

4. Standard tightening torques of bolts and nuts DISASSEMBLY AND ASSEMBLY METHOD OF USING MANUAL

7. Tightening torque of O- ring boss connector

8. Tightening torque of O- ring boss connector

DISASSEMBLY AND ASSEMBLY PRECAUTIONS WHEN CARRYING OUT OPERATION

PRECAUTIONS WHEN CARRYING OUT OPERATION

1. Precautions when carrying out removal work

SPECIAL TOOL LIST

SKETCHES OF SPECIAL TOOLS

REMOVAL OF AFTERCOOLER CORE

INSTALLATION OF AFTERCOOLER CORE

REMOVAL OF FAN GUARD, RADIATOR AND HYDRAULIC OIL COOLER ASSEMBLY

INSTALLATION OF FAN GUARD, RADIATOR AND HYDRAULIC OIL COOLER ASSEMBLY

Water Filling

Filling ( Hydraulic Tank) with Oil

Filling of Air Conditioner Gas

Alignment of Engine Pulley and Fan Pulley

Filling ( Fuel Tank) with Diesel Fuel

REMOVAL OF FUEL COOLER AND AIR CONDITIONER CONDENSER ASSEMBLY

INSTALLATION OF FUEL COOLER AND AIR CONDITIONER CONDENSER ASSEMBLY

REMOVAL OF FUEL TANK ASSEMBLY

INSTALLATION OF FUEL TANK ASSEMBLY

REMOVAL OF ENGINE, PTO AND HYDRAULIC PUMP ASSEMBLY

INSTALLATION OF ENGINE, PTO AND HYDRAULIC PUMP ASSEMBLY

Water Filling

Air Bleeding

REMOVAL OF PTO ASSEMBLY

INSTALLATION OF PTO ASSEMBLY

DISASSEMBLY OF PTO ASSEMBLY

1. Cover

2. Gear assembly

3. Removal of bearing

ASSEMBLY OF PTO ASSEMBLY

1. Bearings

2. Outer race at case end

3. Nipples, plug

4. Gears

DISASSEMBLY OF FINAL DRIVE ASSEMBLY

ASSEMBLY OF FINAL DRIVE ASSEMBLY

REMOVAL OF REVOLVING FRAME ASSEMBLY

INSTALLATION OF REVOLVING FRAME ASSEMBLY

REMOVAL OF SWING MACHINERY ASSEMBLY

INSTALLATION OF SWING MACHINERY ASSEMBLY

DISASSEMBLY OF SWING MACHINERY ASSEMBLY

ASSEMBLY OF SWING MACHINERY ASSEMBLY

REMOVAL OF SWING CIRCLE ASSEMBLY

INSTALLATION OF SWING CIRCLE ASSEMBLY

REMOVAL OF TRACK SHOE ASSEMBLY

INSTALLATION OF TRACK SHOE ASSEMBLY

DISASSEMBLY OF ONE LINK IN FIELD

FIELD ASSEMBLY OF ONE LINK

REMOVAL OF IDLER ASSEMBLY

INSTALLATION OF IDLER ASSEMBLY

DISASSEMBLY OF IDLER ASSEMBLY

ASSEMBLY OF IDLER ASSEMBLY

DISASSEMBLY OF IDLER ADJUSTMENT CYLINDER ASSEMBLY

ASSEMBLY OF IDLER ADJUSTMENT CYLINDER ASSEMBLY

REMOVAL OF RECOIL SPRING ASSEMBLY

INSTALLATION OF RECOIL SPRING ASSEMBLY

DISASSEMBLY OF RECOIL SPRING ASSEMBLY

ASSEMBLY OF RECOIL SPRING ASSEMBLY

REMOVAL OF CARRIER ROLLER ASSEMBLY

INSTALLATION OF CARRIER ROLLER ASSEMBLY

DISASSEMBLY OF CARRIER ROLLER ASSEMBLY

ASSEMBLY OF CARRIER ROLLER ASSEMBLY

REMOVAL OF TRACK ROLLER ASSEMBLY

INSTALLATION OF TRACK ROLLER ASSEMBLY

DISASSEMBLY OF TRACK ROLLER ASSEMBLY

ASSEMBLY OF TRACK ROLLER ASSEMBLY

REMOVAL OF HYDRAULIC TANK ASSEMBLY

INSTALLATION OF HYDRAULIC TANK ASSEMBLY

REMOVAL OF MAIN PUMP ( NO. 1 PUMP) ASSEMBLY

INSTALLATION OF MAIN PUMP ( NO. 1 PUMP) ASSEMBLY

REMOVAL OF MAIN PUMP ( NO. 2 PUMP)

INSTALLATION OF MAIN PUMP ( NO. 2 PUMP) ASSEMBLY

REMOVAL OF MAIN PUMP INPUT SHAFT OIL SEAL

INSTALLATION OF MAIN PUMP INPUT SHAFT OIL SEAL

REMOVAL OF CONTROL PTO LUBRICATION PUMP ASSEMBLY

INSTALLATION OF CONTROL PTO LUBRICATION PUMP ASSEMBLY

DISASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY

ASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY

REMOVAL OF CONTROL VALVE ASSEMBLY

INSTALLATION OF CONTROL VALVE ASSEMBLY

DISASSEMBLY OF CONTROL VALVE ASSEMBLY ( WORK EQUIPMENT)

ASSEMBLY OF CONTROL VALVE ASSEMBLY ( WORK EQUIPMENT)

REMOVAL OF SOLENOID VALVE ASSEMBLY

INSTALLATION OF SOLENOID VALVE ASSEMBLY

REMOVAL OF BOOM DAMPING VALVE ASSEMBLY

INSTALLATION OF BOOM DAMPING VALVE ASSEMBLY

REMOVAL OF SWING MOTOR ASSEMBLY

INSTALLATION OF SWING MOTOR ASSEMBLY

REMOVAL OF CENTER SWIVEL JOINT

INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

DISASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

REMOVAL OF TRAVEL MOTOR ASSEMBLY

INSTALLATION OF TRAVEL MOTOR ASSEMBLY

DISASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

DISASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

REMOVAL OF BUCKET CYLINDER ASSEMBLY

INSTALLATION OF BUCKET CYLINDER ASSEMBLY

REMOVAL OF ARM CYLINDER ASSEMBLY

INSTALLATION OF ARM CYLINDER ASSEMBLY

REMOVAL OF BOOM CYLINDER ASSEMBLY

INSTALLATION OF BOOM CYLINDER ASSEMBLY

REMOVAL OF BOTTOM DUMP CYLINDER ASSEMBLY

INSTALLATION OF BOTTOM DUMP CYLINDER ASSEMBLY

DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

REMOVAL OF BUCKET ASSEMBLY

INSTALLATION OF BUCKET ASSEMBLY

REMOVAL OF ARM ASSEMBLY

INSTALLATION OF ARM ASSEMBLY

REMOVAL OF BOOM ASSEMBLY

INSTALLATION OF BOOM ASSEMBLY

REMOVAL OF WORK EQUIPMENT

INSTALLATION OF WORK EQUIPMENT ASSEMBLY

REMOVAL OF OPERATOR S CAB ASSEMBLY

INSTALLATION OF OPERATOR S CAB ASSEMBLY

REMOVAL OF COUNTERWEIGHT ASSEMBLY

INSTALLATION OF COUNTERWEIGHT ASSEMBLY