Format: PDF

Language: EN

File Size: 78.19 MB

Pages: 289

Printable Content

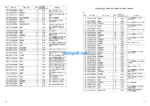

$40.00 Original price was: $40.00.$35.00Current price is: $35.00.

COVER

CONTENTS

GENERAL

1. SPECIFICATIONS

2. POINTS REGARDING LOCAL ASSEMBLY

3. BOLT TIGHTENING TORQUE AND BOLT TIGHTENING TOOLS

4. SEPARATE UNITS

5. LIST OF PARTS SENT INDIVIDUALLY

6. ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE

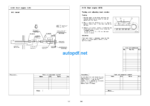

7. KIT LAYOUT DIAGRAM

8. TOOLS AND EQUIPMENT TO BE USED

COMPONENTS TO BE ASSEMBLED IN HARBOR

COOLING SUB ASS’Y

FUEL TANK SUB ASS’Y

HYDRAULIC TANK SUB ASS’Y

SUCTION TUBE SUB ASS’Y

OIL COOLER LINE

SWING MACHINERY SUB ASS’Y

HOOD (SMALL) SUB ASS’Y

RIGHT SIDE DOOR SUB ASS’Y

RIGHT SIDE DUCT SUB ASS’Y

PARTITION COVER

MUFFLER COVER

BATTERY CASE SUB ASS’Y

A. ASSEMBLY OF CHASSIS

A-1: ASSEMBLY OF TRACK FRAME AND AXLE

A-2: TRAVEL MOTOR PIPING

A-3: IDLER CUSHION CYLINDER PIPING

A-4: INSTALLATION OF TRAVEL MOTOR GUARD

A-5: FILLING SWING CIRCLE WITH GREASE

A-6: ASSEMBLY OF REVOLVING FRAME ASSEMBLY AND AXLE ASSEMBLY

A-7: SWIVEL TRAVEL PIPING

A-8: SWING CIRCLE GREASE TUBE PIPING

A-9: INSTALLATION OF LEFT AND RIGHT LADDERS

A-10: INSTALLATION OF LEFT CATWALK (STD)

A-11: INSTALLATION OF RIGHT CATWALK

A-12: INSTALLATION OF CATWALK, HANDRAIL BESIDE OPERATOR’S CAB

A-13: INSTALLATION OF OPERATOR’S CAB LADDER

A-14: INSTALLATION OF OPERATOR’S CAB HANDRAIL

A-16: INSTALLATION OF HANDRAIL AT REAR OF OPERATOR’S CAB

A-18: OPERATOR’S CAB FRONT FRAME, HANDRAIL

A-20: RIGHT DECK HANDRAIL

A-21: INSTALLATION OF LADDER ON TOP OF HYDRAULIC TANK

A-22: INSTALLATION OF COUNTERWEIGHT

A-23: INSTALLATION OF COUNTERWEIGHT LADDERS (LEFT AND RIGHT)

A-24: INSTALLATION OF HANDRAIL ON TOP OF FUEL TANK, COUNTERWEIGHT

A-25: INSTALLATION OF FUEL TANK VIBRATION STOPPER BRACKET

A-26: INSTALLATION OF GREASE REEL, HOSE, BRACKET

A-27: INSTALLATION OF LEFT CAB BASE ASSEMBLY

A-28: INSTALLATION OF OPERATOR’S CAB ASSEMBLY

A-29: INSTALLATION OF WIPER MOTOR COVER INSIDE OPERATOR’S CAB

A-30: INSTALLATION OF UPPER HANDRAIL OF LEFT-HAND DOOR COVER

A-31: HANDRAILS ABOVE THE RH DOOR AND ABOVE THE HYDRAULIC OIL TANK

A-32: EMERGENCY STOP SWITCH, FUEL CUT LEVER

A-33: HANDRAIL ABOVE THE RADIATOR

A-34: CONNECTION OF HYDRAULIC PIPING OPERATOR’S CAB ASSEMBLY

A-35: CONNECTION OF WINDOW WASHER HOSE OF OPERATOR’S CAB ASSEMBLY

A-36: CONNECTION OF AIR PIPING OF LEFT CAB BASE ASSEMBLY

A-37: CONNECTION OF GREASE PIPING OF OPERATION’S CAB ASSEMBLY

A-38: CONNECTION OF WIRING HARNESS IN CAB BASE

A-39: PIPING OF AIR CONDITIONER DISCHARGE HOSE

A-40: INSTALLATION OF HEAD GUARD

A-41: INSTALLATION OF ORBCOMM ANTENNA

A-42: CONNECTION OF BATTERY CABLE

A-43: START ENGINE

A-44: FINAL TIGHTENING OF SWING CIRCEL MOUNTING BOLTS

L-1: INSTALLATION OF LEFT-HAND CATWALK AND POWER-ASSISTED LADDER

C. INSTALLATION PROCEDURES

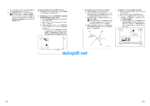

C-1: INSTALLATION OF BOOM CYLINDRE TO CHASSIS

C-2: INSTALLATION OF BOOM CYLINDER PIPING

C-3: BLEEDING AIR FROM BOOM CYLINDER

C-4: BOOM SUB-ASSEMBLY

C-5: INSTALLATION OF BOOM ASSEMBLY

C-6: INSTALLATION OF BOOM CYLINDER TOP PIN

C-7: CONNECTION OF ARM ASSEMBLY TO BOOM

C-8: INSTALLATION OF HOSES BETWEEN BOOM AND CHASSIS

C-9: INSTALLATION OF ARM CYLINDER TOP PIN

C-10: BLEEDING AIR FROM ARM CYLINDER

C-11: INSTALLATION OF HYDRAULIC HOSES BETWEEN BOOM AND ARM

C-12: CONNECTION OF GREASE PIPING

C-13: CONNECTION OF WIRING BETWEEN BOOM AND CHASSIS

C-14: INSTALLATION OF HOSES BETWEEN BOOM AND CHASSIS

C-16: CONNECTION OF BUCKET ASSEMBLY TO ARM

C-17: INSTALLATION OF BUCKET LINK

C-18: BLEEDING AIR FROM BUCKET CYLINDER

M. INSPECTION AND SERVICING PROCEDURES

M-1: INSPECTING THE OIL LEVEL AND WATER LEVEL

M-2: FLUSHING OF HYDRAULIC CIRCUIT

M-3: RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

INITIALIZATION PROCEDURES FOR VHMS CONTROLLER

SETTING PROCEDURES FOR REPLACING VHMS CONTROLLER

FIELD ASSEMBLY INSPECTION REPORT