Format: PDF

Language: EN

File Size: 57.05 MB

Pages: 981

Printable Content

$40.00 Original price was: $40.00.$35.00Current price is: $35.00.

MAIN MENU

COVER

CONTENTS

01 GENERAL

Specification drawings

Specifications

Weight table

Fuel, coolant and lubricants

10 STRUCTURE AND FUNCTION

PTO

PTO lubrication system

Radiator, oil cooler, aftercooler

Power train

Swing machinery

Swing circle

Final drive

Track frame

Track shoe

Air piping diagram

Air circuit diagram

Air governor

Air tank

Safety valve

Horn valve

Grease pump

Hydraulic piping drawing

Hydraulic circuit drawing

Hydraulic tank

Hydraulic pump

Line oil filter

Pilot oil filter

Return oil filter

Drain oil filter

L.H. 5-spool control valve

R.H. 4-spool control valve

Swing motor

Center swivel joint

Travel motor

PPC control relief valve

Safety lock valve

Accumulator

Valve control

Work equipment, swing PPC valve

Travel PPC valve

Solenoid valve assembly

Work equipment

Air conditioner

Actual electric wiring diagram

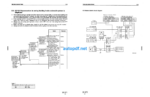

Electric circuit diagram

Engine control

Electronic control system

Machine monitor system

20 TESTING AND ADJUSTING

Standard value table for engine related parts

Standard value table for chassis related parts

Standard value table for electrical parts

Tools for testing, adjusting, and troubleshooting

Measuring engine speed

Measuring air supply pressure (boost pressure)

Measuring exhaust temperature

Measuring exhaust color

Adjusting valve clearance

Measuring compression pressure

Measuring blow-by pressure

Testing and adjusting fuel injection timing

Measuring engine oil pressure

Testing and adjusting alternator belt tension

Testing and adjusting fan belt tension

Testing and adjusting belt tension for air conditioner compressor

Testing and adjusting governor motor lever stroke

Adjusting engine speed sensor

Testing and adjusting hydraulic pressure in work equipment, swing, travel circuit

Testing and adjusting control pump circuit oil pressure

Testing and adjusting piston pump control pressure

Measuring servo piston stroke

Measuring PPC valve output pressure and testing PPC shuttle valve

Testing solenoid valve output pressure

Adjusting work equipment swing PPC valve

Testing travel deviation

Testing locations causing hydraulic drift of work equipment

Measuring oil leakage

Testing clearance of swing circle bearing

Testing and adjusting track shoe tension

Bleeding air

TROUBLESHOOTING

30 DISASSEMBLY AND ASSEMBLY

METHOD OF USING MANUAL

PRECAUTIONS WHEN CARRYING OUT OPERATION

SPECIAL TOOL LIST

SKETCHES OF SPECIAL TOOLS

STARTING MOTOR ASSEMBLY Removal, Installation

ALTERNATOR ASSEMBLY Removal, Installation

NOZZLE HOLDER ASSEMBLY Removal, Installation

ENGINE OIL COOLER ASSEMBLY Removal, Installation

FUEL INJECTION PUMP ASSEMBLY Removal, Installation

WATER PUMP ASSEMBLY Removal, Installation

TURBOCHARGER ASSEMBLY Removal, Installation

THERMOSTAT ASSEMBLY Removal, Installation

AIR COMPRESSOR ASSEMBLY Removal, Installation

ENGINE FRONT SEAL Removal, Installation

ENGINE REAR SEAL Removal, Installation

GOVERNOR MOTOR ASSEMBLY Removal, Installation

CYLINDER HEAD ASSEMBLY Removal, Installation

AFTERCOOLER CORE Removal, Installation

FAN GUARD, RADIATOR, HYDRAULIC COOLER ASSEMBLY Removal, Installation

HYDRAULIC COOLER, AFTERCOOLER ASSEMBLY Removal, Installation

ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY Removal, Installation

PTO ASSEMBLY Removal, Installation

PTO ASSEMBLY Disassembly, Assembly

FINAL DRIVE ASSEMBLY Removal, Installation

FINAL DRIVE ASSEMBLY Disassembly, Assembly

REVOLVING FRAME ASSEMBLY Removal, Installation

SWING MACHINERY ASSEMBLY Removal, Installation

SWING MACHINERY ASSEMBLY Disassembly, Assembly

SWING CIRCLE ASSEMBLY Removal, Installation

TRACK SHOE ASSEMBLY Removal, Installation

ONE LINK IN FIELD Disassembly, Assembly

SPROCKET Removal, Installation

IDLER ASSEMBLY Removal, Installation

IDLER ASSEMBLY Disassembly, Assembly

IDLER ADJUSTMENT CYLINDER ASSEMBLY Disassembly, Assembly

RECOIL SPRING ASSEMBLY Removal, Installation

RECOIL SPRING ASSEMBLY Disassembly, Assembly

CARRIER ROLLER ASSEMBLY Removal, Installation

CARRIER ROLLER ASSEMBLY Disassembly, Assembly

TRACK ROLLER ASSEMBLY Removal, Installation

TRACK ROLLER ASSEMBLY Disassembly, Assembly

TVC VALVE ASSEMBLY Removal, Installation

CO, NC VALVE ASSEMBLY Removal, Installation

SERVO VALVE ASSEMBLY Removal, Installation

NO. 1 PUMP ASSEMBLY Removal, Installation

NO. 2 PUMP ASSEMBLY Removal, Installation

MAIN PUMP INPUT SHAFT OIL SEAL Removal, Installation

CONTROL, PTO LUBRICATION PUMP ASSEMBLY Removal, Installation

MAIN RELIEF VALVE ASSEMBLY Removal, Installation

MAIN RELIEF VALVE ASSEMBLY Disassembly, Assembly

CONTROL PUMP RELIEF VALVE ASSEMBLY Removal, Installation

LEFT 5-SPOOL CONTROL VALVE ASSEMBLY Removal, Installation

RIGHT 4-SPOOL CONTROL VALVE ASSEMBLY Removal, Installation

CONTROL VALVE ASSEMBLY Disassembly, Assembly

SWING MOTOR ASSEMBLY Removal, Installation

CENTER SWIVEL JOINT ASSEMBLY Removal, Installation

CENTER SWIVEL JOINT ASSEMBLY Disassembly, Assembly

TRAVEL MOTOR ASSEMBLY Removal, Installation

WORK EQUIPMENT PPC VALVE ASSEMBLY Removal, Installation

WORK EQUIPMENT PPC VALVE ASSEMBLY Disassembly, Assembly

TRAVEL PPC VALVE ASSEMBLY Removal, Installation

TRAVEL PPC VALVE ASSEMBLY Disassembly, Assembly

BUCKET CYLINDER ASSEMBLY Removal, Installation

ARM CYLINDER ASSEMBLY Removal, Installation

BOOM CYLINDER ASSEMBLY Removal, Installation

BOTTOM DUMP CYLINDER ASSEMBLY Removal, Installation

HYDRAULIC CYLINDER ASSEMBLY Disassembly, Assembly

BUCKET ASSEMBLY Removal, Installation

ARM ASSEMBLY Removal, Installation

BOOM ASSEMBLY Removal, Installation

BUCKET, ARM ASSEMBLY Removal, Installation

WORK EQUIPMENT ASSEMBLY Removal, Installation

OPERATOR’S CAB ASSEMBLY Removal, Installation

COUNTERWEIGHT ASSEMBLY Removal, Installation

AIR CONDITIONER COMPRESSOR ASSEMBLY Removal, Installation

AIR CONDITIONER UNIT ASSEMBLY Removal, Installation

GOVERNOR, PUMP CONTROLLER ASSEMBLY Removal, Installation

MONITOR PANEL ASSEMBLY Removal, Installation

CONTROL STAND CASE Removal, Installation

40 MAINTENANCE STANDARD

Engine mount

PTO

Swing circle

Swing machinery

Final drive

Track frame

Idler

Carrier roller

Track roller

Track shoe

Hydraulic pump

Charging and PTO lubrication pump

L.H. 5-spool control valve

R.H. 4-spool control valve

Swing motor

Travel motor

Center swivel joint

PPC control relief valve

PPC valve

Hydraulic cylinder

Work equipment

Dimensions of work equipment

90 OTHERS

Hydraulic piping drawing (Back hoe)

Hydraulic piping drawing (Back hoe)

Hydraulic piping drawing (Loading shovel)

Hydraulic circuit drawing (Back hoe)

Hydraulic circuit drawing (Loading shovel)

Hydraulic piping drawing (Back hoe)

Hydraulic circuit drawing (Loading shovel)

Actual electric wiring diagram (1/2) (Back hoe)

Actual electric wiring diagram (2/2) (Back hoe)

Actual electric wiring diagram (1/2) (Loading shovel)

Actual electric wiring diagram (2/2) (Loading shovel)

Electric circuit diagram (1/3) (Back hoe)

Electric circuit diagram (2/3) (Back hoe)

Electric circuit diagram (3/3) (Back hoe)

Electric circuit diagram (1/3) (Loading shovel)

Electric circuit diagram (2/3) (Loading shovel)

Electric circuit diagram (3/3) (Loading shovel)

Electric circuit diagram (1/3) (Back hoe)

Electric circuit diagram (2/3) (Back hoe)

Electric circuit diagram (3/3) (Back hoe)

Electric circuit diagram (1/3) (Loading shovel)

Electric circuit diagram (2/3) (Loading shovel)

Electric circuit diagram (3/3) (Loading shovel)

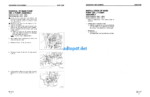

Machine control system diagram

Connector arrangement diagram (1/2)

Connector arrangement diagram (2/2)